The benchmark of organic and inorganic

separation without the return of

emulsified inorganics downstream.

The benchmark of organic and inorganic separation without the return of emulsified inorganics downstream.

Treatment plants around the world are increasingly adopting fine screening technologies to protect their downstream processes. As fine screens operate to reduce the amount of solids in the downstream flow, they do not distinguish between the organic and inorganic material they capture. If the organics are not properly separated from the inorganic material, a wide range of challenges can occur. Biological plant processes can potentially be starved of the organic material they are designed to accept. Disposal costs can soar. Plant odor can quickly become an issue and downstream equipment can be damaged by a flow of disintegrated organic and inorganic material if grinder technologies are used.

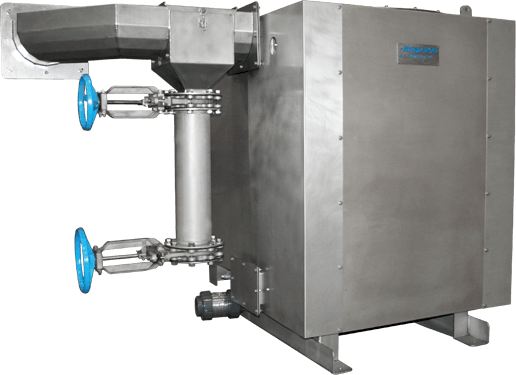

The Thresher Shark Washing Machine is a continuous process that optimally conditions wastewater screenings through the combination of time proven compactor and chopper pump technologies. A multi-chambered stainless steel tank eliminates short-circuiting and ensures all screenings are thoroughly conditioned, unlike single tank/agitator designs.

As screenings and screen wash water pass through the pump, the soft fecal and organic materials are broken down while harder inorganics are chopped. After passing through the chopper pump, the flow is divided between a secondary tank and continued processing through the pump. As the secondary tank is filled, chopped screenings and wash water are directed to the washing compactor. Organic and fecal materials are drained through the compactor back to the screen channel while a finishing wash cleans any remaining inorganic material before compaction and disposal.

The system automatically adjusts to handle high loading and/or multiple online screens. An integral rock trap protects the equipment from dense material. Adjustable weirs automatically bypass in the event the pump or compactor is ever out of service. Maintenance is simplified with all mechanical operations located outside of the tank for easy access.

The key to our Thresher Shark Washing Machine technology is that inorganic materials are not disintegrated and returned to the plant, as they are with maintenance-intense grinder technologies. Instead, inorganic solids are reduced to about 3/8” (9mm) in diameter, making them easy to capture in the drain trough of the washing compactor. The result is ideal separation of organic and inorganic material without disposal of fecal material and tissue paper in the dumpster or return of rags and plastics to the plant.

Do you have any questions or would you like more information?

We’d be happy to hear from you.

4750 118th Avenue North Clearwater, Florida 33762 USA Phone: +1 (813) 818-0777 Fax: (813) 818-0770

Copyright ©2025 Hydro-Dyne Engineering. All Rights Reserved. | Privacy Policy | Terms of Use