superior self-contained

protection for your process.

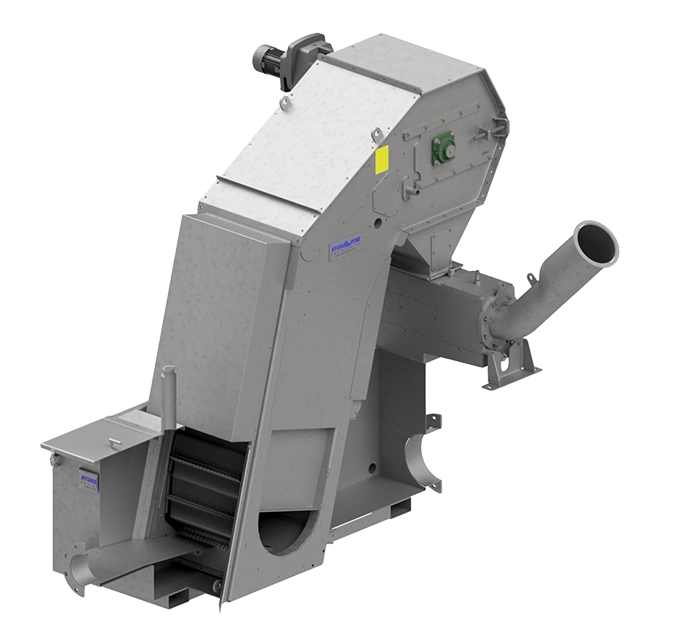

The Dusky Shark is renowned for eating just about anything, including garbage. And like this shark, our Dusky Shark Septage Receiving Station is highly capable of screening nearly any material out of a wastewater flow, including septage and grease trap material that other equipment cannot manage. The Dusky Shark Septage Receiving Station is highly efficient, reliable and easy to install.

[features-benefits-dusky-through-flow][/features-benefits-dusky-through-flow]

We offer opening options that include stainless steel links and perforated panels as well as UHMWPE perforated panels. Our Dusky Shark Septage Receiving Equipment can accommodate low-to-high flow rates and features opening sizes from 1mm to 75mm.

The Laced Link-style grid is ideally suited for water and wastewater applications where fine screening is required with low headlosses.

Flow passes through the screen while solids are intercepted and collected by the continuously moving grid. Solids larger than the openings in the screen’s grid are collected and form a mat, which is removed undisturbed from the flow resulting in extremely high solids capture and easy unloading.

A low profile bottom shoe and polypropylene brush seals the grid, preventing solids from bypassing under the screen. Flow is constantly presented a clean grid surface as solids are transported to the top of the screen. Screenings are discharged into screenings handling equipment.

Minimal friction is achieved through the use of Ultra High Molecular Weight Poly-Ethylene (UHMWPE) and stainless steel wear surfaces. Machined Delrin spacers precisely separate elements, eliminating metal-on-metal wear, reducing power and maintenance requirements and ultimately extending the life of the grid.

Wide stainless steel tracks ensure years of trouble-free operation. Stainless steel grid elements provide superior strength while reducing area and headlosses. Heavy gauge stainless steel links are not susceptible to breaking and damaging downstream equipment.

Level sensing devices can be connected to variable speed drives to automatically compensate for high solids loading during peak flows or low flow conditions by proportionally speeding or slowing the grid travel speed. This increases the capacity of the equipment when needed and reduces wear, thereby extending the life of the equipment.

Patented direct drives efficiently power the screen. Stainless steel sprockets support and pull the black UHMWPE Guide Links, resulting in little-to-no friction and long wear. Most importantly, no part of the drive touches the grid. Therefore, a bent grid element will not be compounded into a disabled screen.

Features:

Do you have any questions or would you like more information?

We’d be happy to hear from you.

4750 118th Avenue North Clearwater, Florida 33762 USA Phone: +1 (813) 818-0777 Fax: (813) 818-0770

Copyright ©2025 Hydro-Dyne Engineering. All Rights Reserved. | Privacy Policy | Terms of Use