Efficient and economical solutions to your grit removal needs.

Hydro-Dyne has a long history of supplying grit removal systems to the municipal wastewater industry. A wide range of products are available to suit grit removal needs. Hydro-Dyne excels at integrating screening and grit together for a comprehensive preliminary treatment system.

Sand Sharks are known for their unique hunting strategy and tendency to swim near the shoreline in the surf zone. Our Sand Shark line of grit equipment also feel at home in sandy environments and are skilled predators with their highly efficient ability to remove grit particles in a variety of wastewater flow rates.

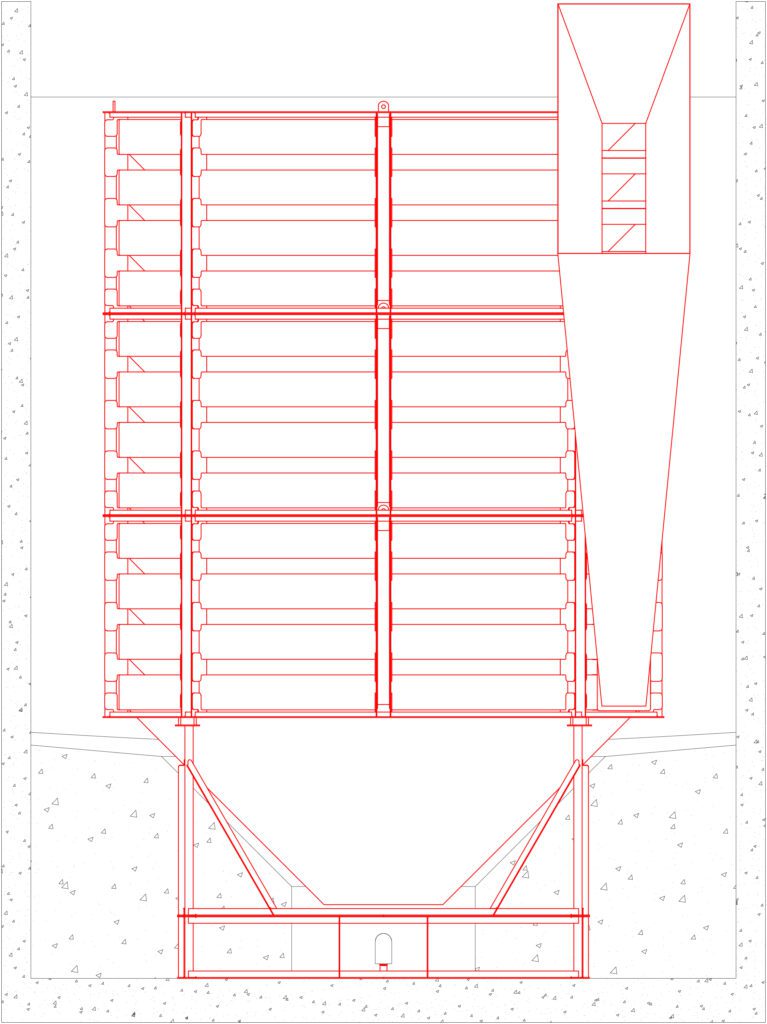

The Sand Shark Circular Stacked Tray (CST) delivers advanced fine grit capture and removal for municipal and industrial treatment plants of all sizes. Engineered for high efficiency and low maintenance, the CST system removes very fine grit, reduces organic content, and integrates seamlessly into new or existing headworks designs.

Grit Removal Capacity

95% of 75 micron particles (2.65 g/cc) at avg flow

Sizes

6’, 9’ and 12’ in diameter trays

Peak Daily Flow Capacity

To 20 MGD (876 L/s)

Peak Instantaneous Capacity

To 20 MGD (876 L/s)

Materials

304/316 stainless steel in concrete or stainless tank

Configurations

270 or 360 degree Inlet/Outlet

Technology & Materials

Operation

Installation

Performance

Coarse Grit Capture

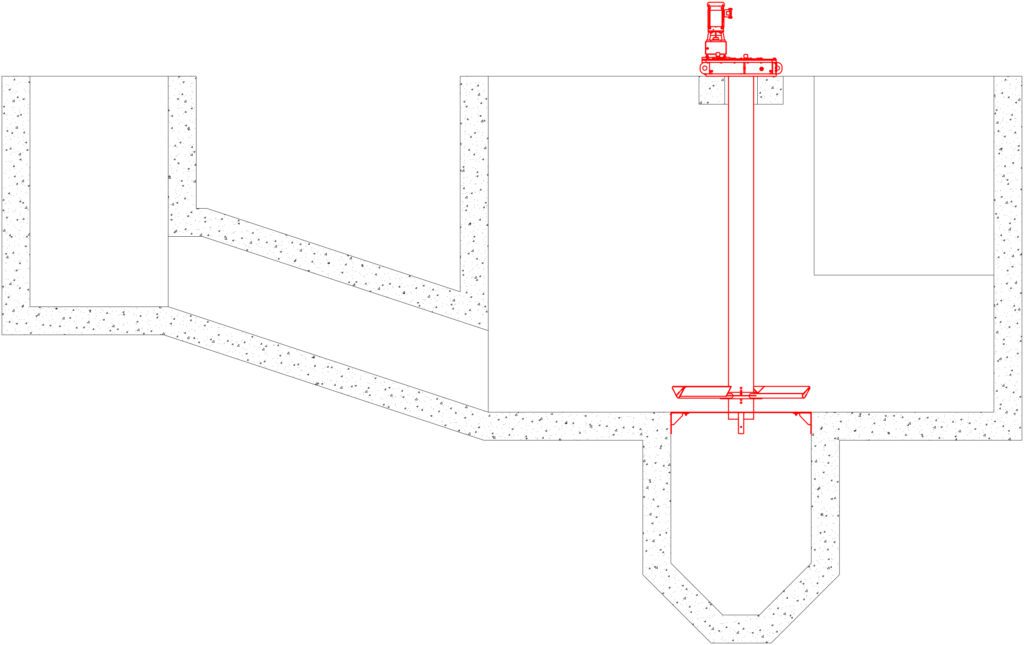

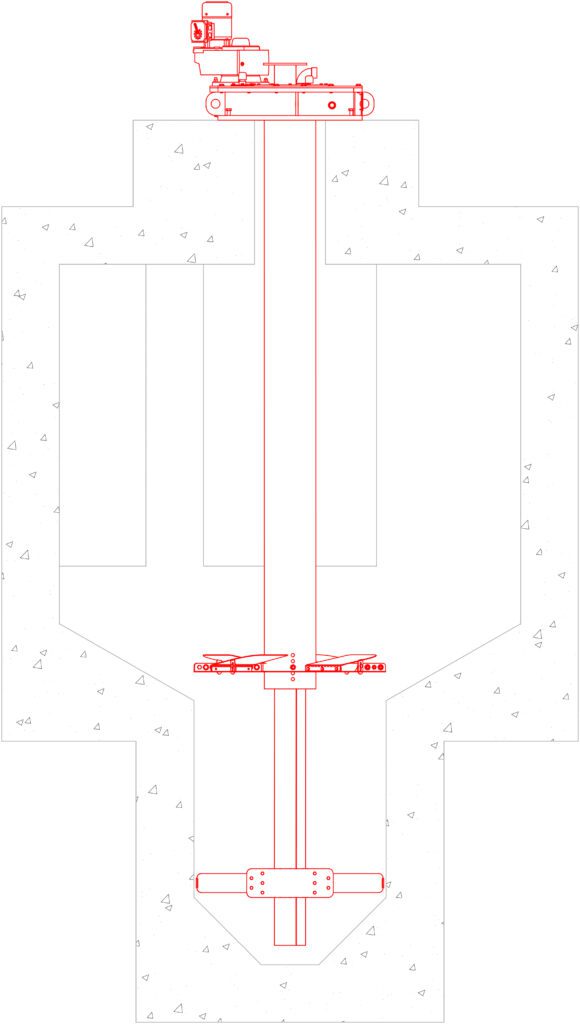

The Sand Shark Grit Trap is a simple, efficient and economical solution to your grit removal needs. In-ground and above-grade models are available for effective, efficient and economical removal of grit from flows up to 70 MGD (3,066 L/s) per unit. Our vortex grit removal system includes a geared drive head and rotating flat plate impeller inside the grit collector. Grit pump or air lift options extract collected grit to the Hydro-Cyclone and classifier.

Single Source Supplier for Total System Responsibility

Grit Removal Capacity

95% of 200 micron particles (2.65 g/cc) at avg flow

Sizes

To 24’ diameter concrete settling basin

Peak Daily Flow Capacity

To 70 MGD (3,066 L/s)

Peak Instantaneous Capacity

To 70 MGD (3,066 L/s)

Materials

304/316 stainless steel in concrete or stainless tank

Configurations

270 or 360 degree Inlet/Outlet / Flat Floor Design

Rotating grit stirring mechanism maximizes grit capture in the storage hopper

Grit Removal Capacity

95% of 300 micron particles (2.65 g/cc) at avg flow

Sizes

To 24’ diameter concrete settling basin

Peak Daily Flow Capacity

To 70 MGD (3,066 L/s)

Peak Instantaneous Capacity

To 70 MGD (3,066 L/s)

Materials

304/316 stainless steel in concrete or stainless tank

Configurations

270 or 360 degree Inlet/Outlet / Flat Floor Design

Rotating impeller maximizes grit capture in the storage hopper

The grit trap will generally be installed immediately downstream of the fine screen. Inflow enters the circular chamber carrying the heavy grit particles, which will be drawn towards the side wall and flow around the edge of the chamber. Gravity settles the grit particles as they travel

this path.

The impeller creates an up-draft that pushes the grit toward the periphery of the chamber. Light organic and inorganic solids are lifted to the surface and ejected with the remainder of flow from the grit trap.

The calm condition around the edge of the chamber allows the grit particles to sink and be guided by the sloped floor to the center of the chamber. Solids will fall underneath the rotating impeller and collect in the bottom of the chamber for storage and removal.

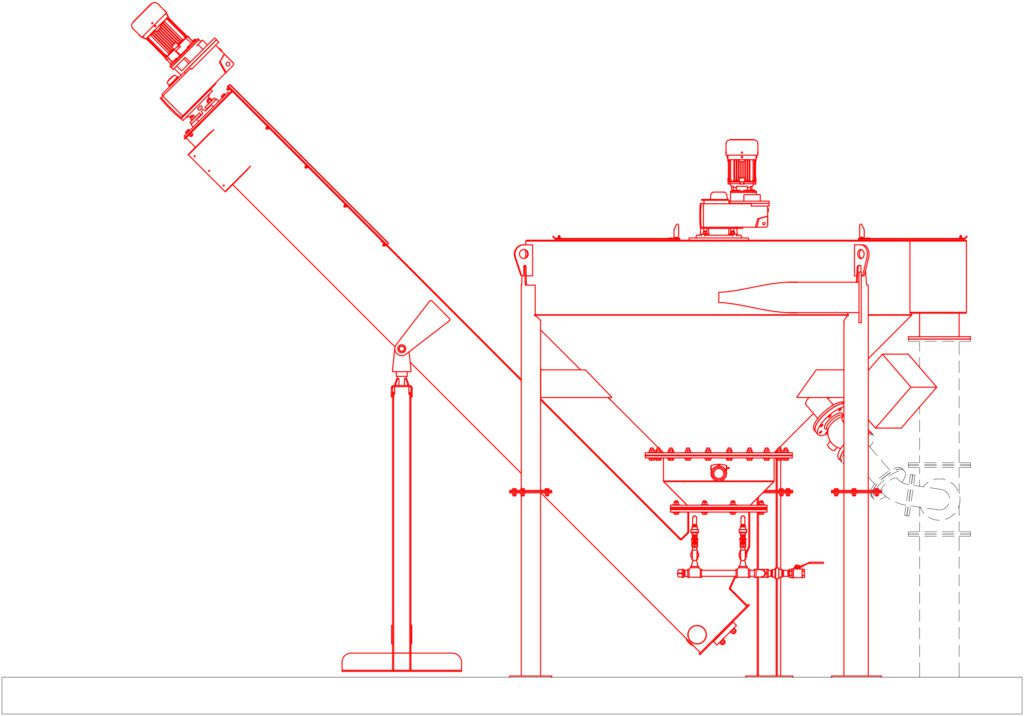

Grit slurry is pumped from the storage hopper at flow rates of 200-250 GPM (12.6-15.8 L/s) directly into the Hydro-Cyclone mounted on top of the Grit Classifier. Excess water exits via the 6-inch overflow and returns to the main flow, generally upstream of the grit trap. The underflow, containing less than 50 GPM (3.2 L/s), and heavy grit solids will be located by the vortex finder and dropped via the outlet cone into the Grit Classifier hopper.

Settled grit will be elevated by a shafted screw that is supported between a top and bottom bearing leaving a 0.5 inch (12.7mm) clearance between the screw flights and the Grit Classifier trough, creating a protective layer of grit. The lower bearing is fully enclosed to prevent the ingress of grit and premature wear of the assembly. The screw lifts the grit from the bottom of the hopper. During conveyance, free water drains back to the hopper while dry grit is elevated and deposited in a receptacle for disposal.

Grit Removal Capacity

95% of 75 micron particles (2.65 g/cc) at avg flow

Sizes

250 gpm capacity

Materials

304 or 316 Stainless Steel

Organic Removal

Up to 95% removal

Operation

Intermittent in most cases

Dewatering Capacity

To 60% solids by wt.

Hydro-Dyne offers a variety of pumping solutions to suit the configuration of the application. The self-primed centrifugal pump is generally used when the grit chamber is cast in-ground. Significant construction cost savings can be realized by mounting the pump at grade. When the grit chamber is elevated it is common to install the suction pipe through the storage hopper wall and install the grit pump in a dry well for ease of maintenance and accessibility. An air lift pump is an efficient method of moving grit from the storage hopper directly to the inlet of the Grit Classifier, without the need for the Hydro-Cyclone.

Grit Pump Options

Do you have any questions or would you like more information?

We’d be happy to hear from you.