Best Practices for Designing a Septage Receiving System

Many wastewater treatment plants and other facilities make the decision to process septage before it enters the treatment process. They do so with a septage receiving station, which removes trash, with a compaction stage, which dewaters and reduces the volume of solid material produced. However, if the septage receiving system is not designed properly, it cannot deliver on the benefits. This blog post discusses some best practices for system design.

Benefits of Screening

Screening wastewater influent is a critical first step to ensuring longer equipment life and offers many benefits, including:

Septage Receiving System Configuration

There are several ways to configure septage receiving equipment. Typically, a system uses a tank mounted screen and compactor. Stainless steel is commonly used for construction to withstand a corrosive environment.

The best septage design utilizes the optimum grid type, screen type, and compaction approach to process the the influent waste stream. Septage is arguably the toughest waste stream input to the wastewater process due to the variable nature of content including rags, rocks, heavy grit, and higher solids content. The offload of material captured on the screen and removal of rocks are also important for successful operation.

Large Debris Removal: Given the potential issues septage represents at the wastewater facility, it is critical that large debris, such as rocks, plastic cartons, plastic wrapping, wipes, rags, clothing and household waste are removed before they have a chance to clog or damage pumps, valves, and other downstream equipment. These items are removed by coarse screens, typically either manually or mechanically cleaned bar screens, with openings of 6 mm (~0.25 in) or larger.

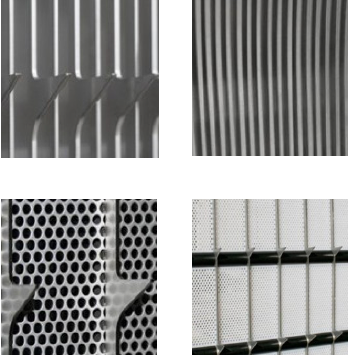

There are many screening grid types available for typical wastewater screening, including slotted link, circular or flat bar, stainless perforated plate, or polymer perforated plate.

Screen Grids (Bar Grid / Perforated Plate Grid)

Rock Removal: Rock removal is also an important feature of septage receiving systems. Some screen types cannot unload large rocks that enter the system, so a rock trap must be used with these types of systems. Rock traps are generally steel vessels with a capture area designed to trap large objects by settling into the bottom of the vessel. Rock traps generally require daily maintenance to remove accumulated material. Close contact with sewage is generally not acceptable if it can be avoided in most treatment operations.

Compaction: Compaction occurs after large solids are removed. Following is the process and equipment used:

In this article we have reviewed the best practices for designing a septage receiving system, for further information about the challenges of septage receiving stations read our next blog post on the topic.

If you would like to discuss your specific needs, connect with Hydro-Dyne’s highly experienced professionals for more information about our Dusky Shark Septage Receiving Station.