SITUATION:

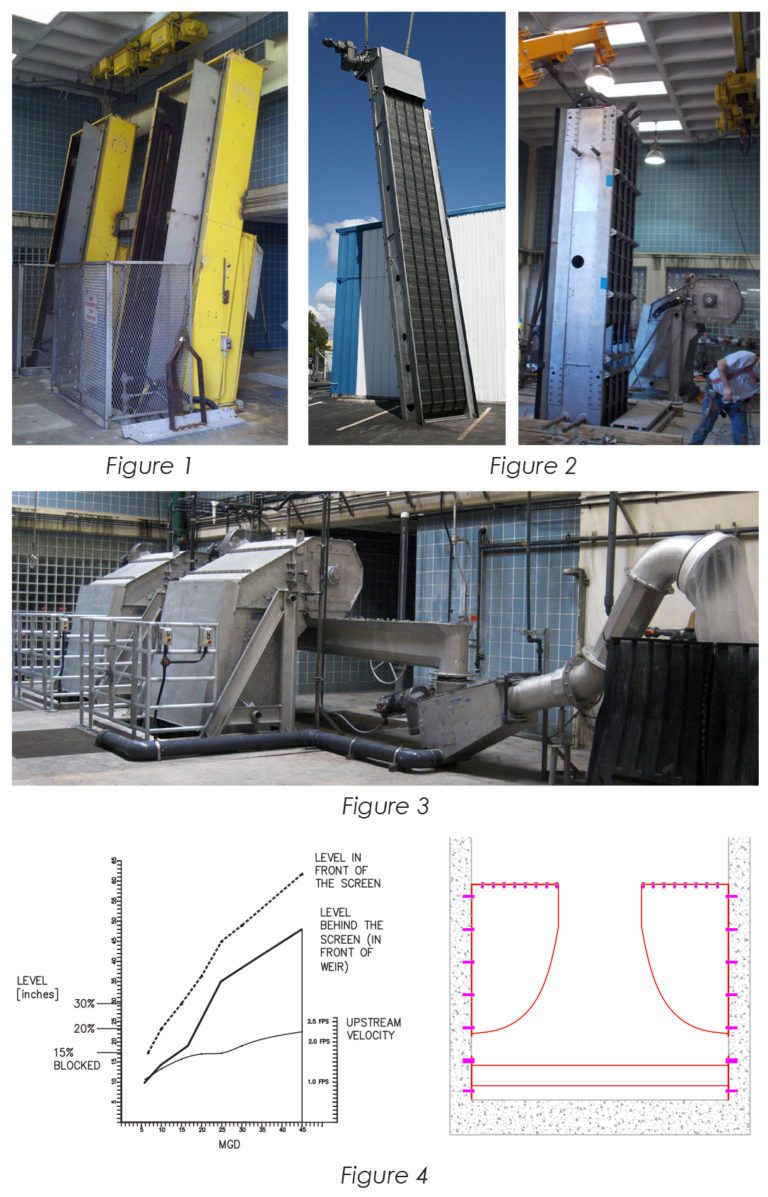

The 45 MGD Cherry Creek Lift Station is one of several sites that pump wastewater to the Southside Wastewater Treatment Plant in southwest Tulsa, Oklahoma. Maintenance had become a serious issue: the single rake bar screens (Figure 1) used at the facility were allowing debris and rags to get through, impacting the operation of the pumps and other downstream processes. The result was that the lift pumps had to be de-ragged on a monthly basis, which was very labor-intensive. Operators had to enter the bottom of the channel to remove debris and to reach routine maintenance areas, as well as deal with other screen access restrictions for maintenance above the channel.

SOLUTION:

In 2013, the City of Tulsa decided to replace the single rake bar screens with a Hydro-Dyne solution consisting of two Hydro-Dyne Bull Shark Heavy Duty Through Flow Screens with 6mm lace link “slotted” grids (Figure 2). These screens provide significantly lower screen height above the operating deck, stainless steel links that can handle large impact loads, higher capture of solids, and can more effectively handle storm flow first flush. In addition, the Hydro-Dyne solution required:

Equipment: Bull Shark Heavy Duty Through Flow Screen

Whitetip Shark Washing Compactor

Sluice

Location: Tulsa, OK

Date: 2013

RESULTS:

The impact of the Hydro-Dyne solution was immediate. By providing a much higher level of protection than the single rake bar screens they replaced, the Bull Shark screens greatly reduced downstream maintenance. In addition, the staff has never had to de-rag the downstream pumps since the screens were installed.

Since screen startup, the station regularly experiences high differential head conditions during storm events, and the screens remain ready to withstand the full design differential of 33ft.

“The screens have performed very well since their installation in 2013,” said the superintendent of the Southside Wastewater Treatment Plant. “In short, their ease of maintenance, solid removal performance, and level of protection is far higher than the screens they replaced.”

The superintendent particularly appreciates the maintenance aspect of the Bull Shark. “Having all of the maintenance items at Operator Level means they no longer have to enter the bottom of the channel and are no longer concerned with restrictive access operations for routine screen maintenance as on other screen designs.”

4750 118th Avenue North Clearwater, Florida 33762 USA Phone: +1 (813) 818-0777 Fax: (813) 818-0770

Copyright ©2025 Hydro-Dyne Engineering. All Rights Reserved. | Privacy Policy | Terms of Use